Бүтээгдэхүүний дэлгэрэнгүй тайлбар

OVERVIEW:

Heating cables are made for a wide variety of industrial, commercial and residential applications. By offering an array of cable technologies — such as self regulating, power limiting, mineral insulated, skin effect, constant wattage and series resistance — our heating cables meet the needs of most applications including process temperature maintenance, pipe freeze protection, longline heating, flow assurance, hot water temperature maintenance, roof and gutter de-icing, surface snow melting, frost heave prevention and floor heating.

Our self-regulating heating cables are the same function as abroad thermon BSX 8-2-FOJ Raychem BTV type .Our heating cable has below feature :

1. Pipeline temperature is uniform, safe and reliable

2. installation and operation costs low, easy maintenance

3. Intermittent operation, warming up fast

4. Save energy and save costs

APPLICATION :

* Pipe Freeze Protection

* Long Pipeline Heating

* Process Temperature Maintenance

* Tank Heating

* Frost Heave Prevention

* Roof Gutter De-lcing

* Surface Snow Melting

Operating Voltage: 110-120 or 208-277 VAC or 380-480VAC

TEMPERATURE :

Max. conductor temperature on continuous: 75℃, 105℃, 135℃

Maximum conductor short time temperature: 105℃, 135℃, 155℃

Minimum construction temperature: -40℃

| Minimum Self-Regulating Indices | ||

| Heating cable | S.R index (W/°F) | S.R index (W/°C) |

| 3 W/ft | 0.038 | 0.068 |

| 5 W/ft | 0.060 | 0.108 |

| 8 W/ft | 0.074 | 0.133 |

| 10 W/ft | 0.100 | 0.180 |

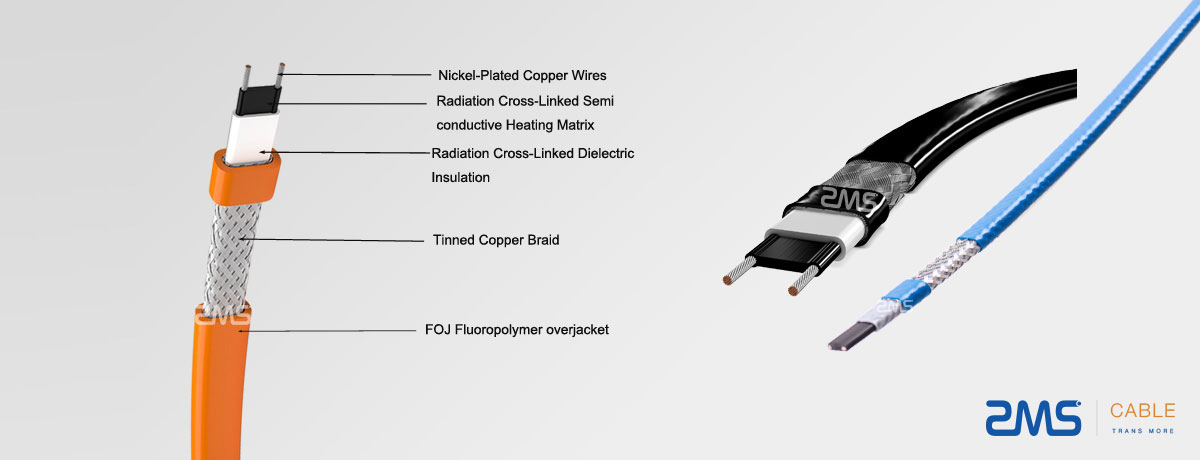

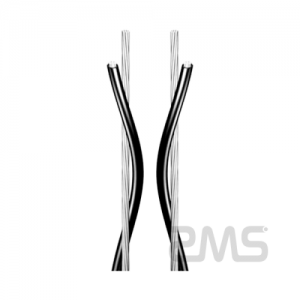

CONSTRUCTION :

| No. | ITEMS | UNIT | TECHNICAL PARTICULARS |

| 2*1.3mm2 | |||

| 1 | Standard Applied | IEC60898 | |

| 2 | Rated Voltage | V | 220 |

| 3 | Number of Cores | No. | 2 |

| 4 | Conductor | ||

| — Cross sectional area | MM2 | 1.3mm2 | |

| — Material | Nickel plated Copper wire | ||

| — Type of conductor | Round | ||

| — No. and dia of strands | Nos./mm | 19/0.3 | |

| — Diameter | mm | 1.6 | |

| 5 | Conductor screen | ||

| — Material | Semi-conductive conductor screen | ||

| — Nominal thickness | mm | 2 | |

| 6 | Insulation | ||

| — Material | Radiation Cross-Linked Dielectric Insulation | ||

| — Nominal thickness | 0.7 | ||

| 7 | Tinned Copper Braid | mm | 0.3 |

| 8 | Jacket | ||

| — Material | Fluoro polymer over jacket | ||

| — Nominal thickness | mm | 0.7 | |

| 9 | OD of the finished cable (Approx.) | mm | 5.3mm*11mm |

| 10 | Weight of the finished cable (Approx.) | Kg/km | 90 |

| 11 | Min. bending radius at laying in terms of cable diameter | D | 10D |

| 12 | D.C Testing voltage | V/min | 2500V/1 |

| 13 | Max. conductor temperature on continuous | °C | 135 |

| 14 | Maximum conductor short time temperature | °C | 220 |

FAQ :

Q: What are Self-Regulating Heating Cables?

A: 1. Any heating cable providing a watt output which increases as temperatures fall and decreases as temperatures rise. Self-regulating heating cables use a carbon matrix-heating element with variable resistance.

2. Self-regulating cables have a conductive polymer-heating element where the resistance exhibits a PTC characteristic, the resistance of the element increases with temperature. Conversely, the cable’s power output decreases with increasing temperature. As the temperature increases the cable power output approaches zero. At this temperature the cable effectively “shuts off”. A hazardous area T-rating can be assigned to self-regulating cables regardless of installation conditions.

3. Being a parallel construction, the self-regulating heating cable can adjust its power output for local condition along its length.

Q: Can TubeTrace be manufactured with different colored outer jackets?

A: Yes, most any color is possible. Additional manufacturing set-up costs may apply.

Q: For heat tracing systems, is thermal insulation really necessary?

A: Yes. The heat losses without thermal insulation are excessive and not practical to compensate for with heat tracing.