Бүтээгдэхүүний дэлгэрэнгүй тайлбар

APPLICATION:

PVC/XLPE power cable is used to transmit and distribute power in power transmission and distribution system of 0.6/1kV or lower.

It is generally applied to the fields including power, construction, mines, metallurgy, petrochemical industry and communication

in complete replace of oil immersed paper insulated power cable and in partial replace of PVC insulated power cable.

TECHNICAL DATA:

| Rated Voltage; (Uo/U)(Um) | 0.6/1kV |

| Max. working; temperature | 70 °c for pvc; insulation and 90 °c for xlpe insulation |

| Max. temperature; during short circuit (≤5S | 160°c (PVC; insulation), 250°c (XLPE insulation) |

| Conductor | class 1 and 2 copper or aluminum |

| Shape of conductor | circular and sectional |

| Shape of conductor | circular and sectional |

| Sectional area | 1.5 – 500mm2 |

| Insulation | PVC / XLPE |

| No. of cores | 1,2,3,4,5,6 |

| Armour | steel wire or steel tape available |

| Sheath | PVC |

| Filler | Polypropylene lament with lapped binding tape |

| Core-covering: | Binding tape |

| Min. beding radius | 15 times cable radius (single core), 12 times cable radius (multi cores) |

CONTENT:

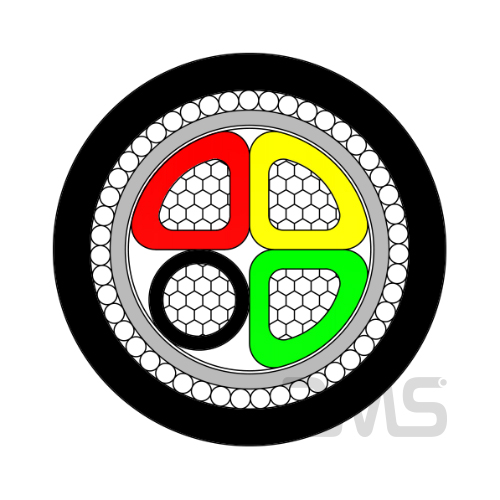

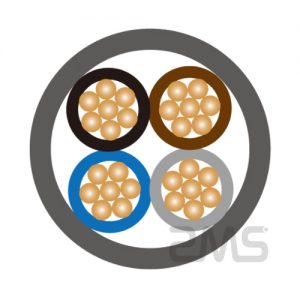

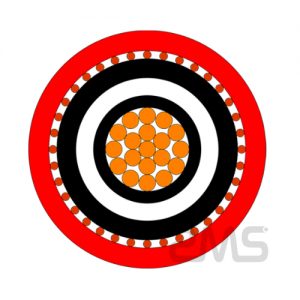

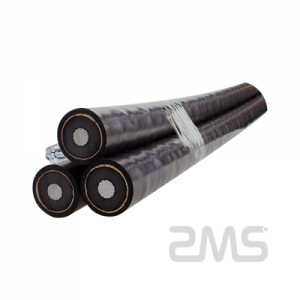

XLPE cable / XLPE conductor / insulated power cable, Low voltage armored XLPE power cable Cu(AL)/XLPE/SWA(STA)/PVC power cable is included the followings:

The products are mainly complying with iec 60502 standard,also can be produced according to OEM requirements and other standards, such as bs standard, din standard, ASTM standard, etc.

0.6/1KV kv multi-cores/ copper or aluminium conductor/ XLPE insulation / copper tape or copper wire screen / galvanized steel wire armored /PVC or PE sheath / power cable, This cable can be installed in duct, tray or direct burial. It is recommended that the installation instructions indicated by the Local Electric Code, or any equivalent, be followed,so that the safeguarding of persons and the integrity of the product will not be affected by eciencies in the installation.

XLPE insulated power cable has a number of advantages over paper insulated and PVC insulated cable.XLPE cable has high electric strength,mechanical strength,high-ageing resisting,environmetal stress resisting antichemical corrossion,and it is simple construction,using convenient and higher operating of long term temperature.It can be laid with no drop restriction.

Various of flame-retardant and non-flame retardant XLPE cable can be manufactured with three technology(peroxide, silane and irradiation crosslinking). The Flame-Retardant cable covers all kinds of low-smoke low-halogen Low-Smoke Halogen Free,and non-smoke nonhalogented and three classes of A,B,C. XLPE cable having higher long-term working temperature and greater current rating,at the same environment XLPE cable may be reduced size(nominal cross-section)1or 2 class in comparison with paper and PVC cable.This is not only improve the quality and properties of products,but also reduce cables production costs.

Some of special XLPE cable can be manufactured according to the other standards required by customs.

STANDARDS:

International:IEC 60502, IEC 60228, (IEC 60332-3 for FR-type only)

China: GB/T 12706, (GB/T 18380-3 for FR-type only)

Other standards such as BS,DIN and ICEA upon request

INSTALLATION:

The installation temperature should not over 20℃, If the ambient temperature is lower than 0℃, the cable should be preheated.

The bending radius of cable should not less than 8 times.

After installantion, the cable should with stand voltage test for 15min. 3.5kv D.C.

ADVANTAGE:

Excellent electric and mechanical characteristics

Simple in structure,Convenient to use

Reduce costs

PACKING AND SHIPPING:

We are capable of meeting the most strict delivery schedules according to per purchase order. Meeting the deadline is always the top priority as any delay in the delivery of cable can contribute to overall project delay and cost overrun. Cable is supplied in wooden reels, corrugated boxes and coils. Cable ends are sealed with BOPP self adhesive tape and non-hygroscopic sealing caps to protect the cable ends from moisture. The required marking shall be printed with a weather-proof material on the outsides of drum according to customers requirement.